NON-DESTRUCTIVE INSPECTION

[Non-destructive inspection that examines things without destroying them] is an inspection method that excels in terms of efficiency and cost. Based on the pros and cons of each inspection method accumulated through our experience, we will deliver a non-destructive inspection system that is optimal for our customers.

From the ultrasonic flaw device, apply a high voltage to the transducer of the ultrasonic probe to generate ultrasonic waves and propagate them on the surface and inside of the inspection material, and measure the reflected signal and propagation time of the ultrasonic waves. This makes it possible to non-destructively inspect the flaws, length and shape inside the material.

Delivery record

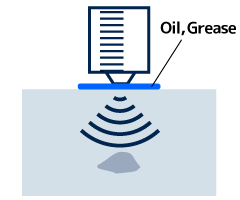

In this method, the ultrasonic probe is brought into direct contact with the inspection part using oil or grease as a contact medium. It is possible to inspect various inspection materials because it is possible to inspect any place where the probe can be contacted regardless of the shape or size of the inspection material. However, it is necessary to consider the contact state of the probe and the surface roughness of the test material.

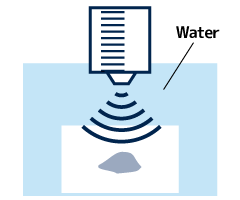

In this method, the inspection material is completely submerged in water (contain anti-rust) for inspection. In this case, since water (medium) exists between the test material and the ultrasonic probe, non-contact inspection is possible By performing non-contact inspection, inspection can be performed without considering the contact state of the probe, making it easier to identify defects. In addition, it is possible to perform inspection by equipping the inspection department However, it is necessary to submerged the workpiece in water and to create a mechanism for inspection.

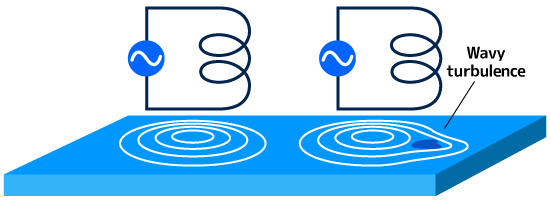

A coil (probe) that generates an alternating magnetic field on the surface of a metal material is used to measure changes in surface conditions such as magnetic permeability, resistivity and cracks of the material from the eddy current generated on the surface of the metal material. This is a method of inspecting for the presence or absence of cracks and judging the material. There are two methods of inspection: one is to pass the test material through the gate-type coil, and the other is to scan the surface of the test material with the probe-type coil.

Delivery record

A hammering inspection is an inspection method that hits an object to be inspected with a hammer, collects and analyzes the frequency of the sound. It is effective for a wide range of inspection objects such as metal, concrete and wood. Hit the material to be measured with a hammer, etc., and determine whether the material has defects or cracks based on the duration of the sound and the results of frequency analysis.

Quantitative inspection that satisfies certain inspection standards can be performed without relying on the experience and intuition of each operator, and inspection results can be automatically saved in the device.

In addition, various products can be inspected.

By installing multiple inspection methods, conventional inspection time can be shortened and complex inspection objects can be inspected. In addition to these application examples of inspection materials and inspection methods, we also propose appropriate inspection methods for various inspection materials. Please feel free to contact us.

We measure the graphite spheroidization rate of steering knuckles (ductile cast iron FCD), which is one of the most important safety parts in automobiles, and inspect flaws such as internal cavities.

"We use ultrasonic waves to inspect unbonded rings and internal defects (holes, cracks, etc.) in ring tregers (cast iron) cast in pistons (aluminum) for diesel engines for unbonded parts and internal defects (cavities, cracks, etc.).

We measure graphite spheroidization rate of ductile cast iron crankshafts using ultrasonic waves, detect detection flaws such as internal cavities at major locations, and inspect for cracks and cracks by hammering sound analysis.

Internal cup crack detection and length measurement of forged cross rolls are inspected by ultrasonic waves.

Ultrasonic flaw detection is performed on important parts of ductile cast iron damper forks, and graphite spheroidization rate is measured as strength evaluation.

Ultrasonic inspection for seal defective as an alternative to shower test.

Detect internal flaws in aluminum wheel ribs and rims with ultrasonic waves. In addition, surface flaws are detected by eddy current testing.

We perform eddy current flaw detection for surface scratches on brake discs (high-carbon cast iron), which are the most important safety parts.

Eddy current inspection for surface cracks after processing cast iron pump cover. In addition, other appearance inspections are examined by image recognition using a camera.

Detects surface scratches and cracks on the inner surface of the liner casting in the cylinder block by eddy current.

Cracks that occur in cast iron products such as knuckles and brake calipers are determined by using a hammering inspection.

Move the ultrasonic probe or inspection material, scan the inspection area, and visualize the inspection results on a map.