Supports Japan's high-quality manufacturing

High-performance non-destructive

inspection system

Order-made product inspection device N.K.System CO.,LTD

Order-made product inspection device N.K.System CO.,LTD

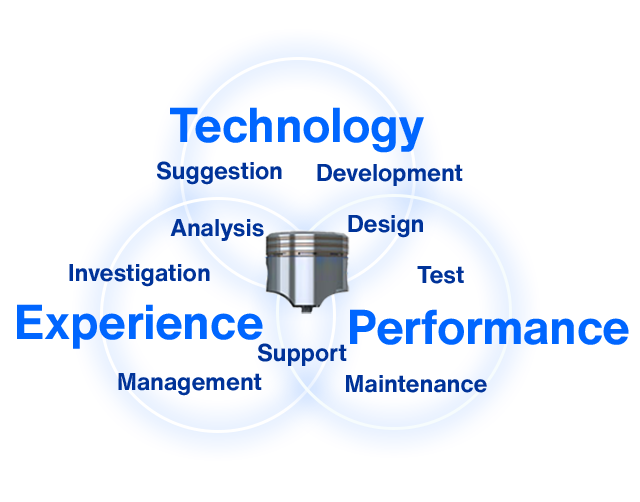

N.K.System provide customer an order-made inspection system.

We'll develop an original non-destructive inspection system that meets yor needs by cooporating many items such as customer's environment, the device you use and each production process.

We provide total support from design to development and operation of custom-made inspection device that cannot be solved by existing systems. Precisely because the system fully incorporates the user's wishes that we are able to produce effective results in quality control.

In an era where a strict quality standards is required Order-made inspection device manufacturer

The inspection method uses changes in eddy currents generated in the inspected object to detect surface cracks and differences in materials.

It is a method to measure internal defects and thickness without destroying the inspection object by propagating ultrasonic waves to the inspection object.

This is a method of inspecting product quality by hitting the inspection material with a hammer and analyzing the frequency of the sound.

We manufacture inspection device that is just right for the customer's environment.

Case Studies

A compact, lightweight and robust tester, Original software development is also possible.

Real-time on-site measurement values are sent to a computer using bluetooth.

YUTIS Inc, Ltd.We will find out the problems in the customer's manufacturing environment and propose the optimum inspection method.

We propose an original inspection system that can be applied to all automobile parts manufacturing lines, such as pistons, cylinders, and differentials.

Based on the results and experience that we have achieved so far, we accurately analyze and understand customer requests, problems and propose solutions.

In principle, our staff visits the site to provide support for order-made device.

This support is possible because of our company, which has a track record of delivery both in Japan and overseas.