CUSTOM MADE

While the quality standards required of the manufacturing industry are at a high level, strict cost down is required. Reducing the rate of defective products is very important for improving the efficiency of manufacturing. This is where quality inspection becomes important. Our company's non-destructive inspection system can collect detailed data without damaging the object. Since it does not destroy the target object, it can be inspected at a minimum cost, and it can also be used for products that does not work, such as buildings. In addition, the collected data can be used to investigate causes, review processes, and select inspection standards, so further efficiency can be expected.

In today's manufacturing sites, where more and more products incorporate precision mechanical device, there are many product parts and the manufacturing process is complicated. Many of them are aggregates of state-of-the-art technology manufactured by the company's own technology. There are many problems with defect inspections of parts manufactured using original materials and processes, such as the inability to obtain accurate data with existing inspection equipment and the inability to perform inspections in the first place. At our company, we propose the most suitable non-destructive inspection method according to the application and request from each user, and support the design, production, and operation.

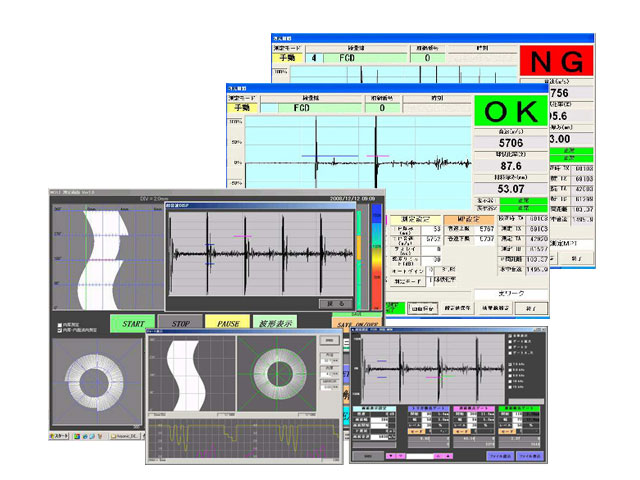

Ready-made products developed for a wide range of customers tend to be equipped with excessive functions in order to respond to various scenes. Therefore, the operation is complicated, and sometimes it is necessary to extract only the necessary parts from the output data and reconstruct them. Complex operations not only require operator skill, but also lead to operational errors such as oversights. Simple operation and easy-to-read data solve all those problems.

When there are many saving inspection points and parts, one existing inspection machine cannot handle it, and multiple units for various purposes must be installed. In some cases, it may also be necessary to modify the production lane. A custom-made inspection machine can be installed in a space-saving and cost-saving because it can be manufactured according to the customer's request, streamlining the work procedure, and matching the style of the site.

Our company does not end with the delivery. We`re also focus on supporting so that the customer continoue to use our product Also,We`re quickly responded to various discomfort as we continoue to use the product such as [it didn`t work for me when i try using it] or [i wanted to change the function due to a change in specifications] can be used in active service.

It is possible to design and manufacture hardware and software in-house. As an advantage of this, it is possible to consistently undertake from the conception of the inspection system to the production and delivery to the customer. Therefore, it is possible to reduce the burden of researching and inquiring about production companies in various fields. In addition, we believe that we can propose the most suitable inspection system by making use of the experience of inspection system production that we have cultivated so far.

At our company, it is possible to plan, design, assemble and adjust inspection equipment in-house. Utilizing our experience, we will propose a system that meets the needs of our customers.

We have developed an inspection program that can run on WindowsOS in-house. Therefore, it is easy to acquire and divert inspection result data. The layout of the inspection screen and the storage of the necessary inspection results are reflected for each customer, so we support accurate data comprehension and operational efficiency.